An often-asked question when I speak to industry groups or receive calls from people in the field is “what are the requirements for containment of point of service protection within the plumbing code?”

In truth the code does not address containment protection. Plumbing codes deal with cross-connection control within the consumers water system, the protection at each and every fixture or appliance. A gray area exists in many areas and jurisdictions across the United States. I am always surprised when I speak with individual’s working in the cross-connection division of a water supplier who have no idea what the adopted plumbing code or regulations are in their area for internal backflow protection, and see no reason to reach out to the plumbing industry. On the flip side many in the plumbing industry see no reason to work with the water suppliers in any meaningful way. Where is the line where the water purveyor or water supplier’s jurisdiction ends, and the plumbing code jurisdiction begins? There are many variables to this equation which include:

- Is there an adopted plumbing code within the jurisdiction? Has it been amended?

- Who is enforcing the plumbing codes or regulations concerning cross-connection protection?

- Is the water supplier within the jurisdiction a public or private entity?

- Is the primary agency setting the regulation on a statewide or on a local basis?

- Who has the responsibility for enforcement of the regulations?

- What, if any, training is required for the public or private individuals or entities involved in the inspection or implementation of the cross-connection control program?

- Is the water purveyor using containment protection, isolation protection, or a mixture of both?

Why are these questions important? Because cross-connection control is never a one size fits all program. Some areas have the situation well in hand, while others have little or no enforcement of any kind. Every month we read about areas that have had backflow incidents – they occur in cities and towns that have no program or regulations in place even though the state in which they are located has had rules in regulations in place for at times twenty years or more. In my experience the best programs combine a water supplier containment program with an active isolation program, using the plumbing code to ensure the proper protection is installed and regulations are in place to regulate the testing and inspection of the internal backflow protection.

This allows for a clear picture of the requirements and of the responsibility for inspection and enforcement. It also, hopefully, ensures that the people in charge of enforcement and inspection have the required experience and knowledge to carry out the tasks ahead of them. Even in areas where both the water supplier and the building and inspection department are part of the same municipality there is little or no communication or cooperation between the groups. Everyone has their own kingdom. We need for these group to work in concert with each other.

How do we define containment protection? Using the 3rd Edition IAPMO Backflow Reference Manual, containment is defined as: A water supplier’s backflow prevention policy of installing backflow protection after the public distribution system service connection and prior to any branch of the water distribution system. With containment protection, the water supplier determines the degree of hazard the facility contains and then ensures the required protection is installed and properly maintained. It is important that after installation of the proper cross-connection protection the facility is periodically inspected or surveyed because changes in occupancy do happen and uses and degrees of hazard may change over time.

Isolation protection is defined as: Backflow Prevention protection installed at each fixture or appliance outlet. This protection is regulated in the adopted plumbing code or regulation. Many methods, devices or assemblies are used in isolation protection. The degree of hazard is again the deciding factor in the type of protection installed.

If we look at the decision the water supplier or purveyor makes as to implementing a containment or isolation program, logic tells us that it containment is an important first step in cross-connection control. By requiring the installation of protection at the service connection, and by monitoring the testing and maintenance of these assemblies or devices, the purveyor or supplier can have confidence that no matter what alterations the consumer makes within the building or facility, at a minimum, the rest of their customers will be protected. Some in our industry believe that this protection is unnecessary and that any water downstream of a backflow preventer must be considered non-potable. That would be true if every area of our nation had an aggressive enforcement and inspection program in place which would mandate regular cross-connection control surveys be conducted of each and every facility or residence and that the proper protection was installed, tested, and maintained. I don’t think that is a realistic approach in the current political climate where governments mandates are very unpopular, and a number of elected officials seem to relish removing regulations as quickly as possible with little or no thought of the danger to our public water systems.

Whether we are speaking about commercial, industrial, or residential facilities it is difficult if not impossible to ensure that additions or alterations are not made within the consumer’s potable water, irrigation, or fire protection systems after the initial inspections by water suppliers or by building and plumbing inspection departments. In a perfect world, permits, plan review, proper installation by qualified and trained personnel and follow up inspections would always take place. The problem is that we don’t live in a perfect world and the perfect world does not exist. In my experience, it is a fact that jurisdictions who allow for isolation protection without requiring containment protection at the water service connection or at the water meter are putting their system and its consumers at an unnecessary risk.

In containment protection programs, a list of the types of facilities in the jurisdiction can be made. By examining this list, it can be determined which facilities usually contain high or low health hazards, the manner in which the potable water system is used, and the actual or potential risk of a backflow incident occurring. An initial determination of the type of assembly to be installed at the facility can be made at this time and preparations for installation can begin. Of course, before the determination of the required protection takes place an inspection of the facility must be made to verify the type of hazard which may affect the water system.

In many instances both containment and isolation surveys will be required. A cross-connection control survey that includes both containment and isolation is far more extensive than a containment only survey. This type survey should only be performed by professionals thoroughly familiar with water distribution system applications. This survey will begin at the service piping entering the property and follow through to every water fixture or appliance connection. The individual or individuals conducting the survey must have a strong background in plumbing code requirements and a clear understanding of the piping systems, along with knowledge of the equipment and fixtures installed with the facility.

Within today’s modern buildings many different type piping systems are being installed. The use of reclaimed water, rainwater catchment systems and other green plumbing makes a complicated job even more complicated. Pipe labeling, and identification becomes critically important when installing these systems. The number of actual and potential cross-connections which occur because of these systems will vary from installation to installation, but the importance of properly protecting the potable water system never changes. Installers, designers, inspectors, and water purveyors must understand the interworking of these systems, the hazards they present and the protect they require.

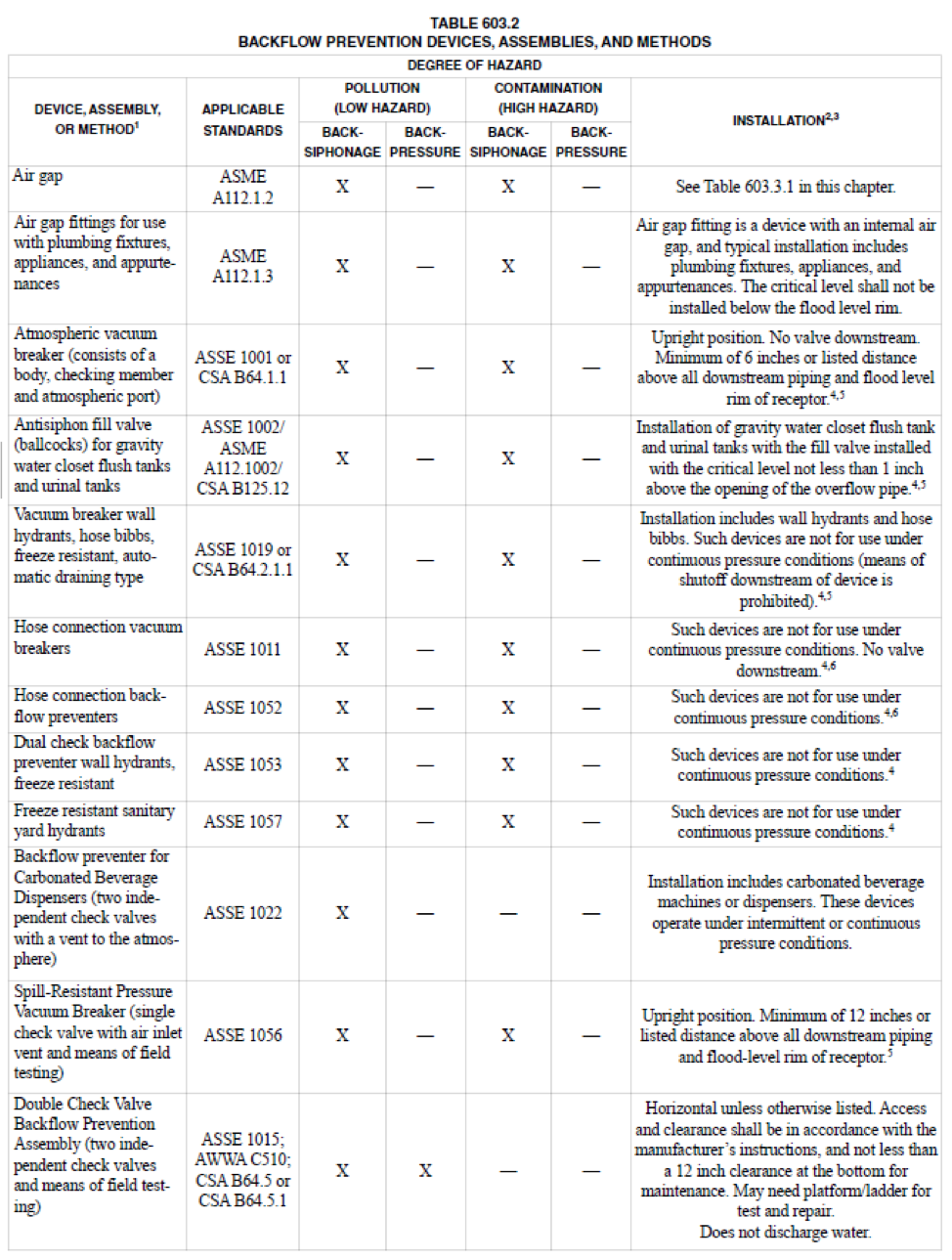

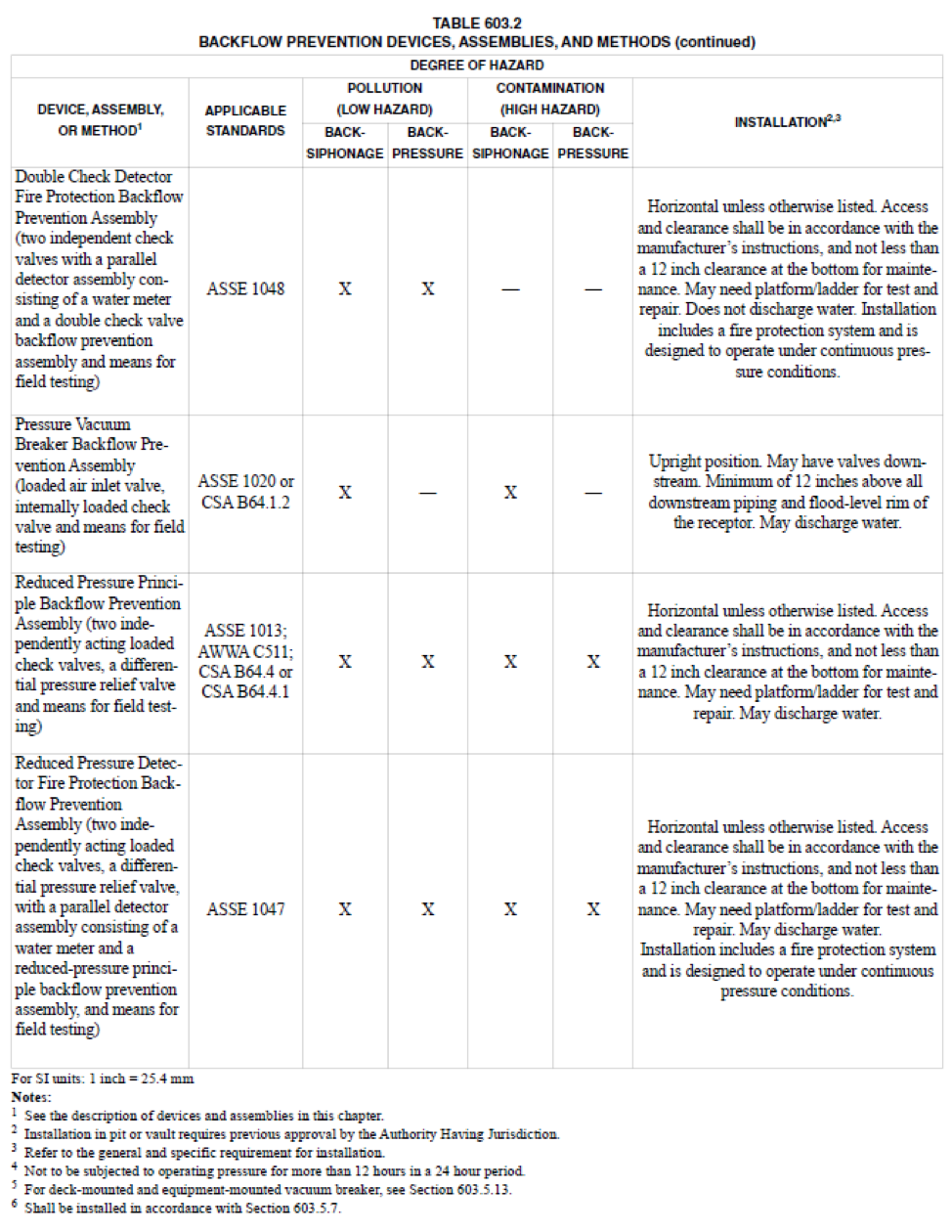

Isolation protection required with a facility, residence, or complex is contained in the adopted plumbing code. All three model codes used within the United States, the Uniform Plumbing Code, the International Plumbing Code, and National Standard Plumbing Code list these requirements as do all state authored codes. All three of these codes also clearly state that, all assemblies installed anywhere in the system for containment or isolation protection will be tested when installed, when repaired, and at a minimum on an annual basis. It is important for anyone in the industry have knowledge of the adopted code and of any additional amendments or regulations related to cross-connection control. The 2018 Uniform Plumbing Code Table 603.2 contains installation requirement for each type of device, method, or assembly along with the hazard level of protection and the applicable product standard.

Using this table and additional information found within chapter six and in other areas of the Uniform Plumbing Code, the installer, consumer, and inspector can find the correct method, device or assembly needed for almost any fixture or appliance protection within the potable water system. Using the adopted plumbing code makes uniform inspection and installation requirements easy to find and understand. The adoption of a prescriptive plumbing code removes many of the gray areas and eliminates the problems that arise when inspectors and installers have different interpretations of the regulations. Too many times decisions are made based on past practices, which may or may not be correct. Other times it is the opinion of a person who may not have the knowledge and experience required to evaluate or understand the system hydraulics or hazard contained in every application or installation.

A clear understanding of any system is needed before the completion of any cross-connection survey or inspection. Training and experience are critical elements in comprehending the interworking of today’s complex plumbing and piping systems. It is more important than ever that each link in the water supply chain, from the water operator at the supply to the consumer at the sink understand the importance of cross-connection control. That is why communication between the water purveyor or supplier, the public health department, the plumbing inspection community and the plumbing industry is more critical now that it ever has been in the past. As budgets tighten and more areas move their plan review, plumbing, and building departments to third party inspection companies, training becomes more vital than ever before. The use of multi-craft inspectors is growing across the United States. Many public and private water suppliers are under pressure to cut costs and are reducing their workforces. In too many instances these cuts impact cross-connection control department and their personnel.

Stronger partnerships need to be made with all the stakeholders involved in setting up, maintaining, and expanding cross-connection programs across the country. The importance of both containment and isolation protection and stable uniform requirements using the plumbing code regulations within a facility simply makes sense. Dialog, cross-training, and cooperation between all parties involved will make any program more successful. Backflow incidents are still happening on a daily basis in areas of the United States. The sad thing is with proper protection all of these problems can be eliminated. One incident is one too many.

About the Author |

|

|

Sean is a 40 year member of the United Association Local 524 Scranton Pa. He has worked in all phases of the plumbing and mechanical industry and is a licensed master plumber. Sean is a Past President of the American Society of Sanitary Engineering. Sean is also the member of the ASSE Cross-Connection Control, Technical Committee. Sean is employed by IAPMO as the Vice President of Operations for the IAPMO Backflow Prevention Institute. |

28 Nov 2018

28 Nov 2018

Posted by Sean Cleary

Posted by Sean Cleary

3 Comments

Great read and something I have often wondered about Sean. In WI we are required by code to provide containment to only sewerage treatment facilities conforming to our Dept of Natural Resources code and to marinas, wharves and docks where potable water outlets are provided to serve boats or ships. We have no requirements for containment for hospitals, factories, or other public buildings.

Great article Sean, in Michigan the MDEQ Cross Connection Rules specifically require local water authorities to comply with the Michigan Plumbing Code and Residential Code as it relates to cross connection control in its entirety. The Michigan Code currently adopts the 2015 IPC and IRC with State amendments. The State Safe Drinking Water Act Rules address containment by granting the water authority the ability to require containment when water lines can not be traced to their end uses.

I’m glad you addressed the need for water authorities and plumbing inspectors to work together. In our community both departments work closely together. The water authority writes violations based on the plumbing code and requires a permit to be pulled per that code to bring the plumbing inspector into the loop for his inspection. By doing this we are pretty much on the same page and communicate on a daily basis.

Awesome article I have ever read.Well explain the importance of plumbing cod and its uses.This article is really helpful. Thanks for sharing this article, please keep sharing with us