Having visited areas all around the United States conducting cross-connection training, talking with industry people, conducting cross-connection surveys, and fielding questions from individuals about problem installations I am still surprised at how often the adopted plumbing code is ignored regarding the installation of backflow preventers. Why don’t we just follow the plumbing code?

As an example, the plumbing code is clear concerning the installation of backflow prevention assemblies in pits and vaults, the 2018 Uniform Plumbing Code states in Section 603.4.9 Prohibited Locations:

Backflow prevention devices with atmospheric vents or ports shall not be installed in pits, underground, or submerged locations. Backflow preventers shall not be located in an area containing fumes that are toxic, poisonous, or corrosive.

This section makes it quite clear that Reduced Pressure Principle Assemblies, Pressure Vacuum Breakers, Spill-Resistant Vacuum Breakers, Atmospheric Vacuum Breakers, and several other backflow preventers simply cannot be installed in pits or vaults. It seems back and white to me.

In reality many reduced pressure principle assemblies have been and in many areas are still being installed in pits or vaults. Some jurisdictions allow for what are called berm installations. These installations require a drain to daylight feature with the drain being sized to match the relief valve discharge of the installed assembly. A drain to daylight can allow animals and insects along with cold temperatures to access the pit or vault. The drain to daylight can also become blocked, which may allow the backflow preventer to become submerged. These installations are occurring in areas where temperatures may allow for the assemblies to be damaged by freezing temperatures. However, there are code approved solutions to freezing temperatures.

The code states in Section 603.4.7 Freeze Protection:

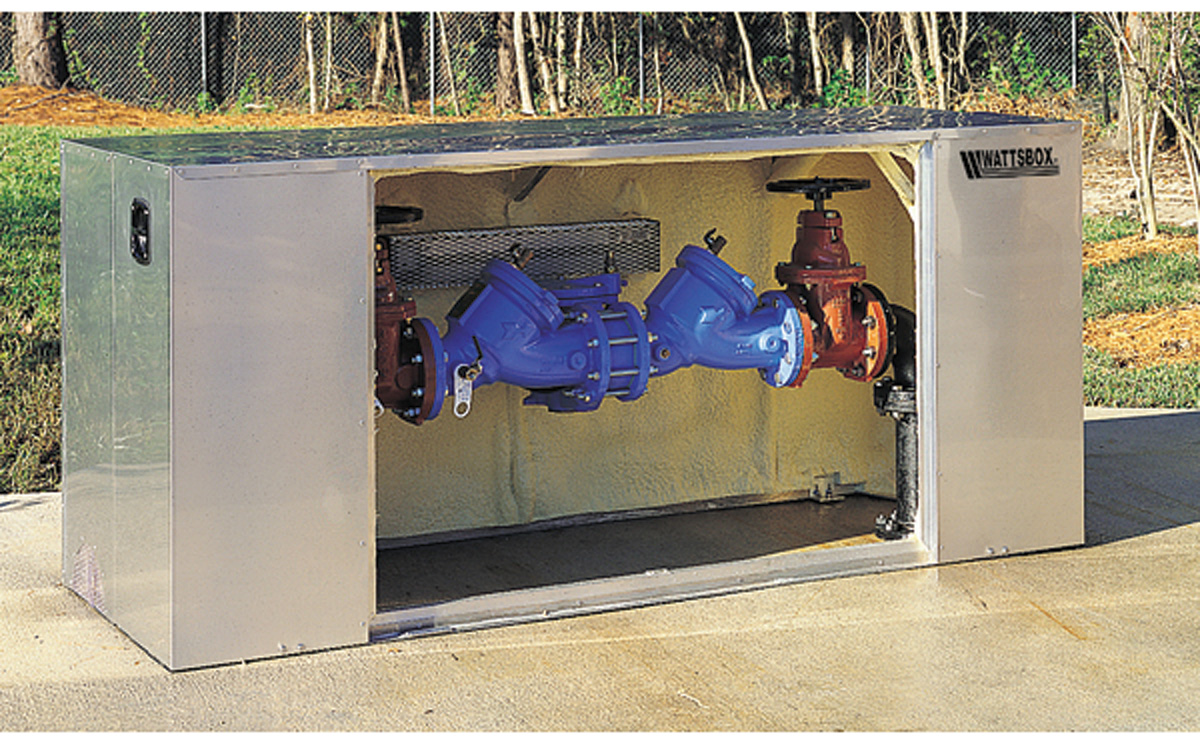

In cold climate areas, backflow assemblies and devices shall be protected from freezing with an outdoor enclosure that complies with ASSE 1060 or by a method acceptable to the Authority Having Jurisdiction.

The use of a Type One ASSE 1060 standard compliant enclosure will allow for assemblies to exist in temperatures of up to minus thirty degrees Fahrenheit. (above) An enclosure will also eliminate the issue of testing and maintaining a backflow prevention assembly in a confined space. Working within a confined space, if done correctly by trained and certified workers in accordance with OSHA regulations increases the cost dramatically and can put personnel into a potentially dangerous situation. It simply makes sense not to install several types of backflow protection, it is also a code violation. We need to follow the code and stop these sub-standard installations.

Another common problem is accessibility for testing and repair. Again, the Uniform Plumbing Code is clear on installation standards. It states in Section 603.4.3 Access and Clearance:

Access and clearance shall be provided for the required testing, maintenance, and repair. Access and clearance shall be in accordance with the manufacturer’s instructions, and not less than 12 inches (305 mm) between the lowest portion of the assembly and grade, floor, or platform. Installations elevated that exceed 5 feet (1524 mm) above the floor or grade shall be provided with a platform capable of supporting a tester or maintenance person.

A backflow preventer is a mechanical device which requires testing and at some point, in time will require replacement or repair. Installing it near the ceiling or another inaccessible location is both a code violation an example of poor workmanship. (above) A true craftsman will follow both the code and the manufacturers installation instructions. In too many cases the backflow preventer is installed in a location where the installation is simple but future testing and repair may be difficult or impossible.

For some backflow protection installations, a drain may be required. The Uniform Plumbing Code states in section 603.4.8 Drain Lines:

Drain lines serving backflow devices or assemblies shall be sized in accordance with the discharge rates of the manufacturer’s flow charts of such devices or assemblies.

In the case of large reduced pressure principle backflow preventers, the discharge rate of the assembly’s relief valve may exceed the maximum capacity of the building drain of a facility. This problem must be addressed when the initial installation takes place. (above) Other backflow protection that may require the installation of floor drains or discharge piping include pressure and atmospheric vacuum breakers.

The code also contains installation requirements cross-connection protection methods, devices, and assemblies. It clearly spells out the requirements for air-gaps, the minimum heights for vacuum breakers, along with installation and accessibility standards for all types of cross-connection protection. How is it that we keep seeing problem after problem occurring? A pet peeve of mine is the far too common, incorrect installation of flushometer valves on water closets and urinals. (below)

The code is clear on this requirement stating in Section 603.5.1 Atmospheric Vacuum Breaker:

Water closet and urinal flushometer valves shall be protected against backflow by an approved backflow prevention assembly, device, or method. Where the valves are equipped with an atmospheric vacuum breaker, the vacuum breaker shall be installed on the discharge side of the flushometer valve with the critical level not less than 6 inches (152 mm), or the distance according to its listing, above the overflow rim of a water closet bowl or the highest part of a urinal.

How is it that the industry continues to get this wrong and inspectors do not insist that this work match the adopted code? (below)

As with so many things the answer is in education and enforcement. We have the requirements in place, what is lacking is insisting that things be installed correctly be qualified, licensed tradesmen and women and inspected by individuals who understand and strongly enforce the adopted code requirements and installation standards. We need to continually educate both the industry and the public on the vital importance of codes and standards. Let’s not settle for anything but the best. If we see issues we need to point them out and use them as teaching opportunities. There is a right way and a wrong way to do things, let’s try to get everyone working in the same direction.

About the Author |

|

|

Sean is a 40 year member of the United Association Local 524 Scranton Pa. He has worked in all phases of the plumbing and mechanical industry and is a licensed master plumber. Sean is a Past President of the American Society of Sanitary Engineering. Sean is also the member of the ASSE Cross-Connection Control, Technical Committee. Sean is employed by IAPMO as the Vice President of Operations for the IAPMO Backflow Prevention Institute. |

25 Sep 2018

25 Sep 2018

Posted by Sean Cleary

Posted by Sean Cleary

5 Comments

Funny you should mention this. I just got called to repair an irrigation device installed 15 feet in the air. and the supply and feed are all with in 3 feet of the ground. How did the plumbing inspector pass that off?…Likely never saw it hidden in the ceiling

Thanks

The installation of a backflow prevention device is only one part of the solution. Some city water suppliers do not enforce the anual testing of the device. When a problem of backflow occurs and people’s water is tainted with out knowledge of it who’s to blame when people become ill?

I am a plumbing and gas piping inspector for Seattle – King County. Our office and our public utility district (Seattle Public Utilities) strictly enforce backflow protection and find that most building contractors are amicable and do want to comply with the codes but are just unaware most of the time. One example being that most builders do not know that if a structure containing plumbing fixtures 30′ or higher above the city water meter are required to provide premise isolation with backflow and back-siphonage protection on the water main serving the structure. This has come up a lot lately due to the huge rise in tall “Townhomes” or “Rowhouses” being built in Seattle. Most of these structures are 40′ or higher. The building dept. allows this, so instead of building one single family home on a typical lot they can build 3 or 4 “Rowhouses”. They call this condensed housing with “0” lot lines.

I liked that you said that proper care is required of backflow assemblies and devices in order for p[roper function. I would agree that freezing temperatures could damage the system if not properly enclosed. I would be sure to hire a professional for correct installation and protection. That way the backflow assemblies and devices would continue to work, even through freezing winter months.