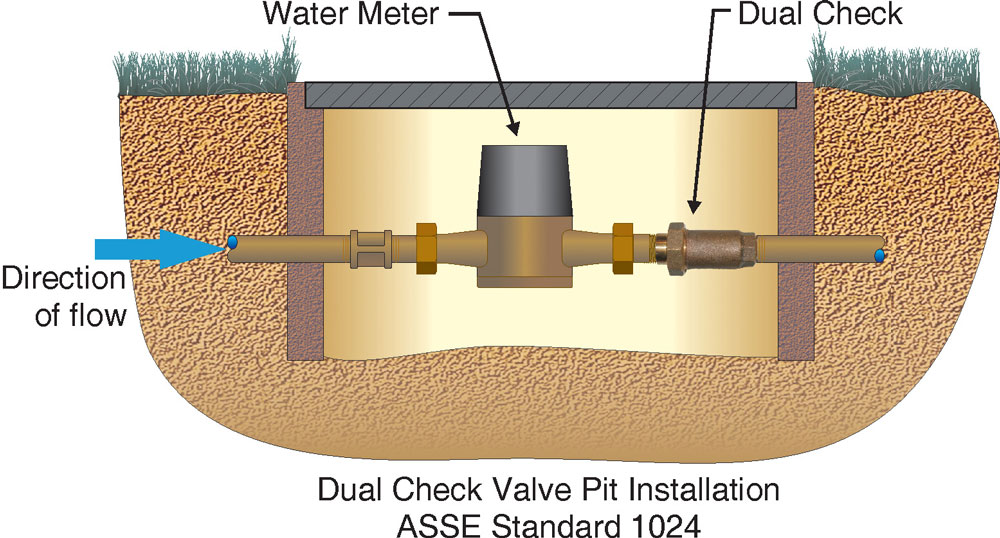

Within the cross-connection industry there are a number of opinions on how important the installation of containment protection is or in some cases if containment programs are even necessary at all. To get started we need to answer what containment protection is. Containment protection is the installation of backflow protection at the water service connection to a residence or facility. It can be as simple as the installation of a dual check valve at a residential meter or as complicated as the installation of a reduced pressure principal assembly in a heated enclosure installed at the curb line of a commercial or industrial facility. It can be a high hazard or low hazard application and may consist of multiple valves in a parallel installation, depending on the facility served and their water needs. While it is true containment protection does nothing to ensure the quality or safety of the water in the facility itself, it does provide vital protection to the entire public water system.

There are a number of people in the industry who think the installation of containment protection is not needed, and some who passionately argue that everything downstream of a backflow preventer must be considered non-potable water, so a containment assembly installed at a water meter means all the water in the facility itself is non-potable. I disagree with this line of thinking on a number of levels and feel that the second line of defense provided by containment protection far out ways the cost of the protection.

Others push for what they call containment by isolation. This idea has merit when an aggressive and expensive regular inspection program is in place. If each and every fixture and appliance is protected, and that protection is tested and maintained, then containment protection is simply unnecessary. This idea however, assumes a number of factors are in place and will remain in place. It only works when everyone understands and plays by the rules. Are we sure that whenever any change is made within a system, a permit is issued, and an inspection takes place? This is one critical weakness in any containment by isolation program. Do it yourselfers, unlicensed contractors, building owners, maintenance personnel, and so many others may make small or even large changes to the internal water systems within a facility. Something as simply as the removal of a hose bibb vacuum breaker can have deadly effects. The lack of regular testing of isolation protection is another widespread problem that exists in many jurisdictions in the United States. All these factors make the installation of containment protection necessary, prudent, and reasonable.

When we do move forward with a containment program there are factors to consider. Is it needed in all buildings? How about residential applications? Does it always need to be a testable assembly, or will a device be the proper protection is many cases? Does the containment device or assembly need to meet the highest level of isolation protection in the facility? What is the answer to these and other questions concerning containment protection? In every case we need to look at each system and application as a unique situation. When we do that, we can ensure the correct protection is in place. It in not a one size fits all situation.

How do we decide what if any containment protection is needed? If any chance of backflow is possible then, yes containment protection is a reasonable step to take. First, we need to look at the system and determine the degree of hazard. Is it a low or high hazard situation? In truth these are the two choices we have available, there is not a no hazard category because hazards are simply part of any modern plumbing system. When we look at containment protection for the selection of the proper protection of the facility it is important to consider the degree of hazard of any fixture or appliance within the facility regardless of any isolation protection installed at that location. In a high hazard location, a backflow incident could result in illness or death to anyone who comes in contact with the substance in the water. In a low hazard location, a backflow incident will affect the atheistic quality of the water but would not cause illness or death.

Once we know the degree of hazard within the system, we can now look at valve selection. In order to do that correctly we need to also know the type of backflow that may occur. For isolation protection it may be possible to see situations where only backsiphonage is possible and a vacuum breaker can be all the protection required. That is almost never the case for containment protection. Containment protection normally requires protection against backpressure and backsiphonage backflow. In my career the only containment pressure vacuum breaker I ever installed was on a water service that supplied an irrigation system to a specific area with no other fixtures or connections. The service came off the public main to a meter vault and then to the irrigation system for a green space which contained a welcome sign for a public park. As I said earlier, every situation should be looked at as a unique installation. Do not take anything for granted, for again we do not live in a one size fits all world.

It is important to remember that if containment protection is installed, it should always match the highest hazard level in the facility. If you have a reduced pressure principle assembly installed as the isolation protection on the make-up supply to a chiller or boiler, then the containment valve should be a reduced pressure principle assembly. The same is true on a fire protection system. If the system contains an antifreeze loop or other chemical additives, then the containment valve should be a high hazard assembly not a low hazard double check valve assembly. This is the case even if the antifreeze loop is protected by a reduced pressure principle assembly isolating it from the rest of the fire protection system.

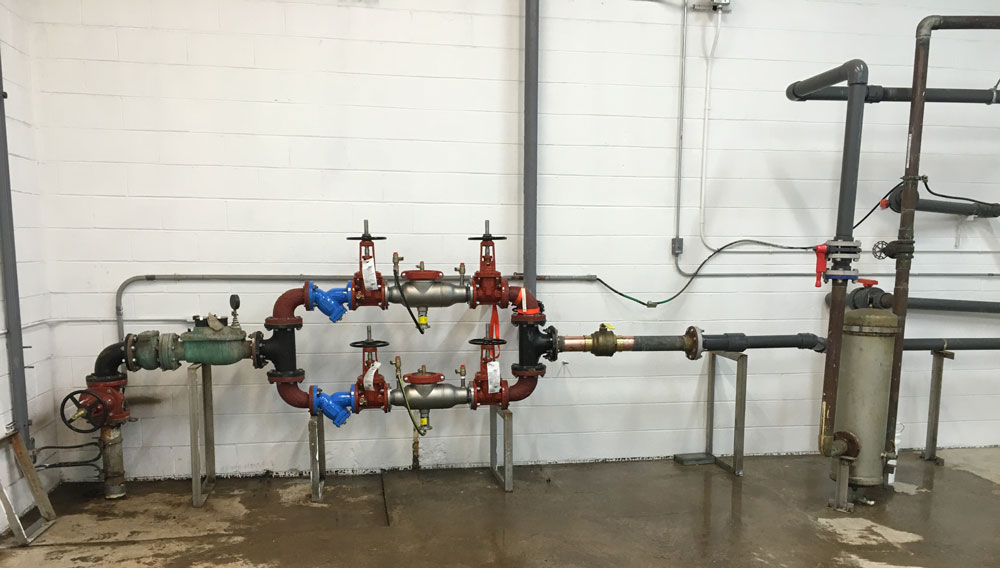

The installation of a testable containment assembly on a water service will require annual testing at a minimum. This requires that the assembly be placed in a static condition. Depending on the field test procedure used, this means the water service will needed to be turned off during any testing, unless an additional assembly in parallel is installed or a bypass around the assembly is in place. Turning the water off to any existing building or facility is something to be avoided. Depressurizing a system can lead to a number of issues including flushometer and automatic valves problems, dirt, and debris issues when the system is restored, and the stress on the system piping when it is depressurized and then repressurized. None of these occurrences are good for a piping system.

When I was working in the field doing installations on new or existing buildings I always pushed for parallel installations or a small bypass being installed around the backflow preventer to allow water pressure to be maintained during the testing or the servicing of the containment protection. If we are doing a bypass installation around an existing backflow preventer it is critical that an assembly of equal protection is installed in the bypass piping. Common sense tells us this, however many times we find unprotected bypasses installed. It is not an uncommon thing to find when conducting cross-connection surveys. It is also commonly found on both isolation and containment applications. I have argued with building owners and contractors that inform me that no where in the plumbing code does it state that bypasses are required to have backflow protection installed in them. The plumbing codes do not address the subject of bypasses with specific code language, they do simply require that protection be installed to prevent backflow. Adding an unprotected bypass around the required protection violates the requirement that the system be protected from backflow.

Another consideration to look at when installing containment protection is that we create a closed water system when we install a valve that creates non-return barrier. This will create a thermal expansion issue and is true in every type of system with or without water heating equipment. Thermal expansion can result from ambient temperature changes within a facility. Uncontrolled thermal expansion can lead to backpressure issues with assemblies and can harm system components and piping. Thermal expansion control must be addressed in any containment program on both residential and commercial water services.

Many areas look at residential water services as being a non-issue when it comes to requiring cross-connection protection. Other have decided to require the protection of a low hazard non-testable dual check. Some in the industry are opposed to installing anything but a testable assembly and allow no other options. In speaking with decision makers in the water industry it is clear that many consider mandating testable assemblies on residential services to be the third rail in backflow protection, something any discussion of should be avoided at any cost. Mandating testable assemblies on residential services is like kicking a beehive and running way. Who pays for the installation and the annual testing costs? In commercial situations most business owners look at these costs are part of doing business. Homeowners are a different breed. They push back on these costs especially if it is a public water supplier. They call the mayor or city council to complain. Even with a good public education program it is a difficult situation at best. This is where compromise needs to take place. We need to look at each residential property as a stand-alone situation and decide what protection is needed. If a non-test device is reasonable then that is what should be installed for containment and a hard look should be taken to ensure the necessary isolation protection is installed.

Using my own home as an example I have a number of fixtures and appliances connected to my water system. Being a licensed master plumber and having built a new home about 17 year ago I know the domestic water system and the hazard it presents. The home has 3.5 baths, 4 frost proof hydrants, two laundry sinks, a dishwasher, a refrigerator with a water dispenser and ice maker, a washing machine, and an indirect water heater connected to a hydronic heating boiler. In addition to the kitchen sink I have a bar sink and being a plumber with a love for beer I installed a wall hung urinal with a Sloan flushometer in my lower-level bath. I live in the Northeastern part of the United States and heat my home with a hydronic radiant heating system which is connected to my water system for make-up water and pressure. Our local water company requires the installation of a non-testable dual check on all residential water services and in most cases including the one I have described in my own home I would agree with them, as long as the isolation protection was in place according to adopted plumbing code. The problem is without a survey how do we know for sure? What if I add a lawn irrigation system into the mix? What if I add snowmelt to my sidewalks or driveway and added antifreeze to the home heating system as a result? Doing so will drastically change the hazard level on the water service. Again, there is no one size fits all solution. Most homes in our water company’s jurisdiction do not have irrigation systems and even fewer have snow-melt systems but the possibility exists.

What the proper containment protection does is add a second line of defense to our water system protection. It makes cross-connection protection programs better and safer. It does not make them failsafe and perhaps the worst unintended consequence to containment protection is it may make inspectors and water suppliers less vigilant to problems and dangers and give them a false sense of security. The good of the programs far outweighs any potential issues. In a perfect world with the proper isolation protection in place containment protection would not be required. The problem is we do not live in a perfect world.

If you agree or disagree on the need for containment protection, please let me know your thoughts on the subject. We welcome different views and opinions, and our goal is to always try to provide as much insight and information as possible.

About the Author |

|

|

Sean is a 40 year member of the United Association Local 524 Scranton Pa. He has worked in all phases of the plumbing and mechanical industry and is a licensed master plumber. Sean is a Past President of the American Society of Sanitary Engineering. Sean is also the member of the ASSE Cross-Connection Control, Technical Committee. Sean is employed by IAPMO as the Vice President of Operations for the IAPMO Backflow Prevention Institute. |

30 Dec 2020

30 Dec 2020

Posted by Sean Cleary

Posted by Sean Cleary

1 Comment

Great article and presentation Sean, lots of good take-aways. That infamous maintenance bypass we always provide is going to get redesigned to include contamination control. Love this industry, never ending learning experience, 46 years and counting.