Question:

I am working on a 4” Wilkins model number 375AST. Can you explain how to service the check valves and relief valve?

Mark:

The Wilkins 375AST is a reduced pressure principle assembly. The series began production in 2011. The valve body is made of stainless steel and has grooved end connections for the shut off valves. The repair procedures for the 375AST series are similar to the 375A (ductile iron body) series, but it is important to note that the internal parts are different and do not interchange. No special tools are needed to repair this assembly. The 375AST has a single access cover has no spring load and is secured by a grooved coupling. This assembly has check valves that are modular in design and are sometimes referred to as “compound checks”.

Doug:

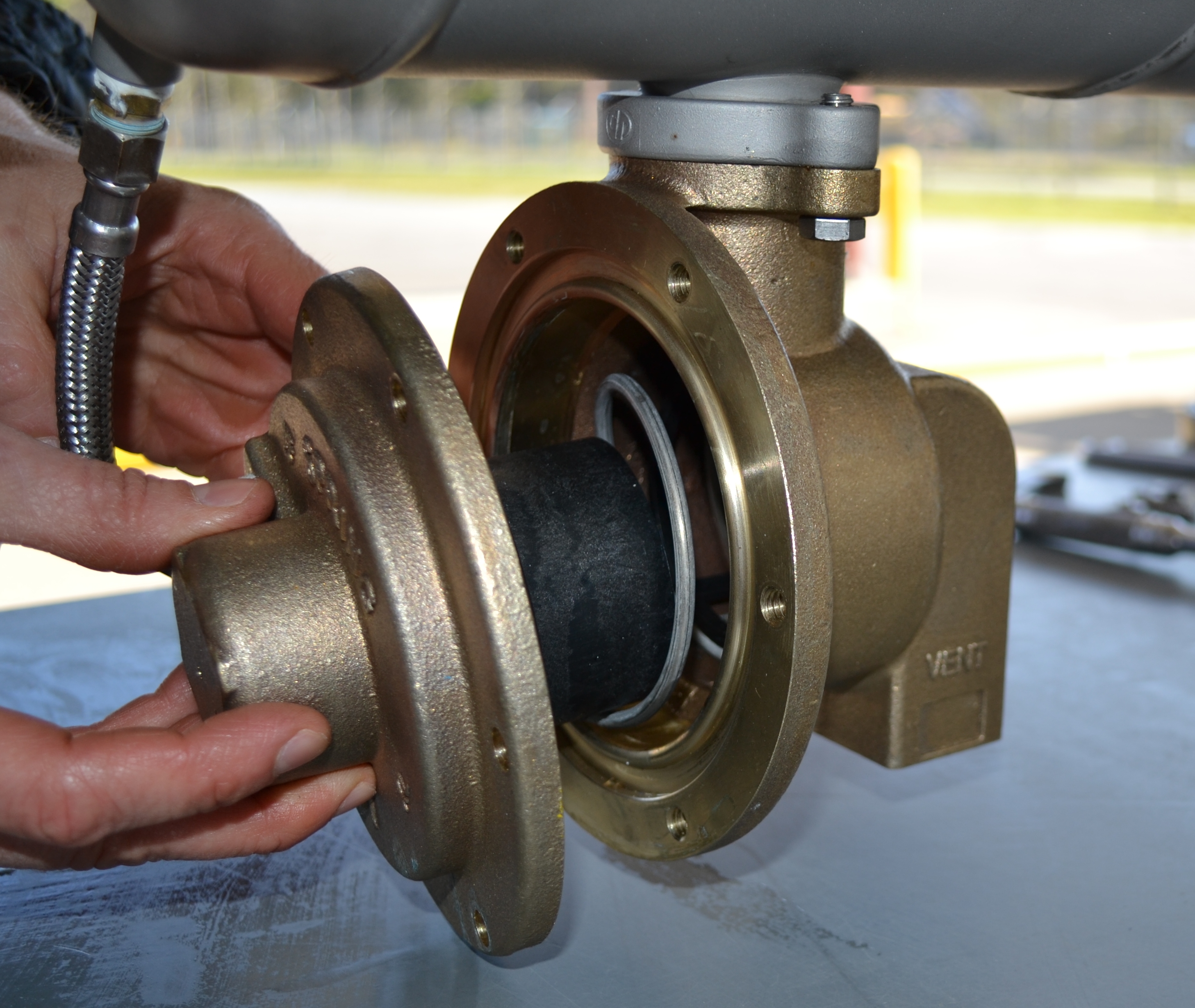

To service the check valves, they must be removed from the device. The checks are secured by a retainer and sealed by an o-ring. Once the access cover has been removed, you will see the plastic ring retainer for the first check valve. The tabs for the retainer are exposed at the 12 o’clock position. Simply pinch the tabs together, push down, and then pull downstream. The first check can now be removed by pulling it straight out of the body.

The second check is secured by two separate spring loaded plate retainers. They are located at the 12 and 6 o’clock positions. Pinch the sides of the spring together and rotate the plates out of the body groove, one at a time. The second check can now be removed by pulling it straight out of the body.

Mark:

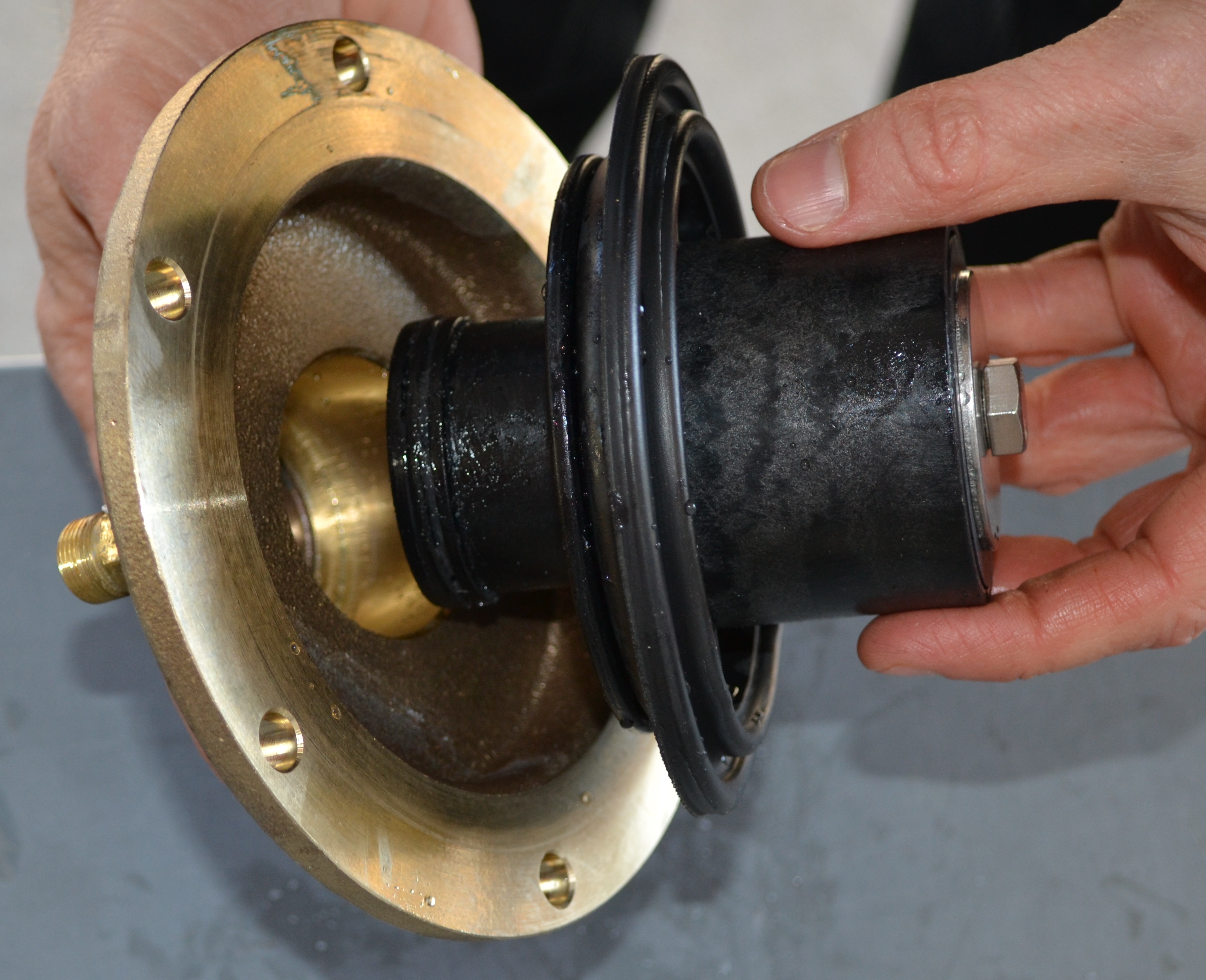

Now that the check valve modules have been removed, we must disassemble them to access the check discs. Note that the spring tension is contained when the check is taken apart. Be cautious to not remove any hardware from the spring side of the module. The downstream side of the check will have 4 hex head bolts that need to be removed. Once they have been removed, you can separate the disc retainer from the module and the disc is free to be replaced. It is also important to inspect the seat. The seat is an integral part of the check module, so if there is any damage, the entire check must be replaced. Once that service has been completed, simply reassemble each module in reverse order.

Doug:

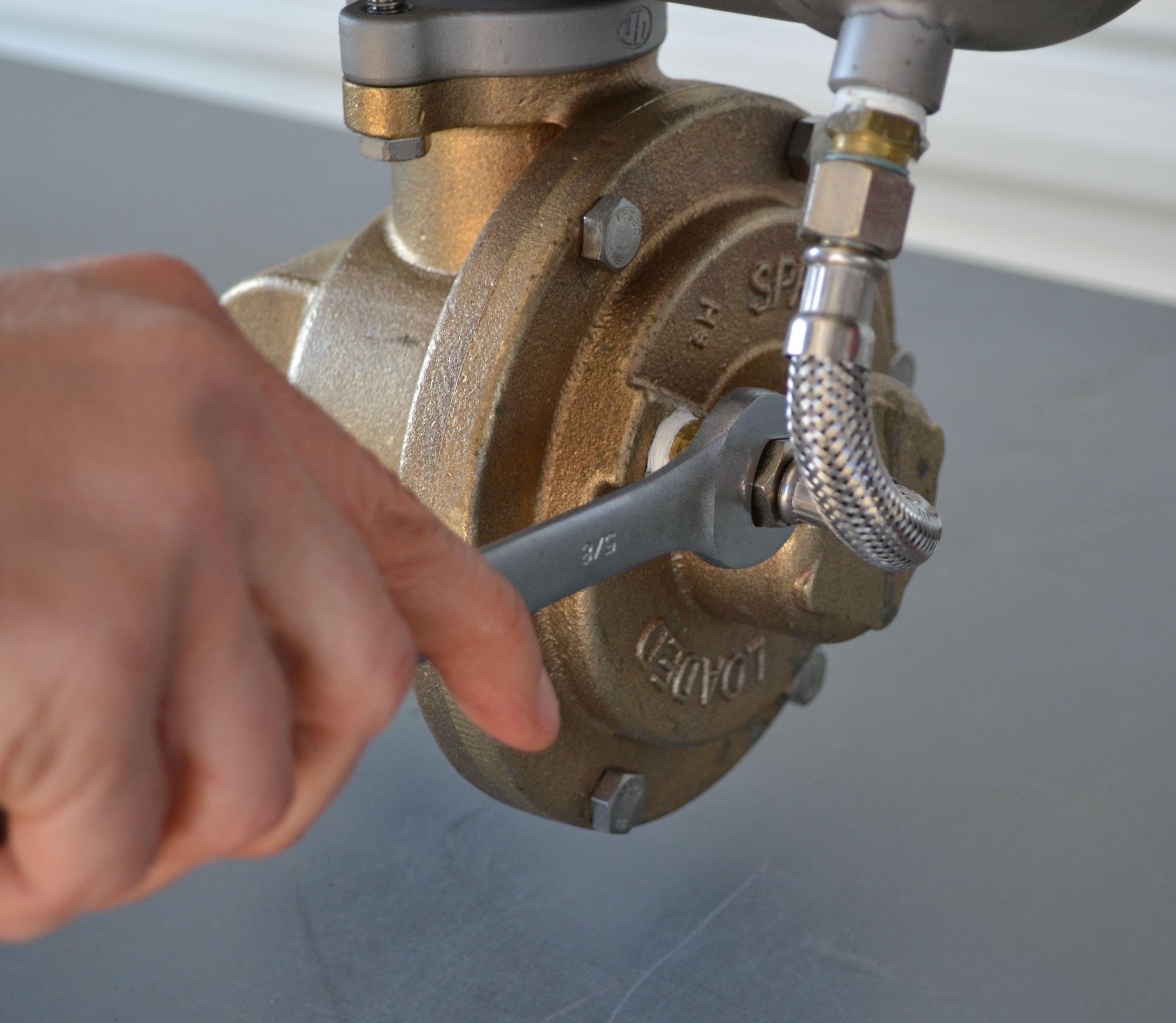

The relief valve cover is secured by six bolts and sealed by the diaphragm. When removing the cover, make sure to disconnect the sensing line before loosening the bolts.

The RV stem assembly and spring are free once the cover has been removed. To service the RV stem assembly, simply remove the retaining bolt and separate the stem and piston. Once the stem assembly has been disassembled, the diaphragm and seat disc are free and can be replaced. During reassembly, it is important to note that the bead on the diaphragm will line up with the groove on the RV body. The flat side of the diaphragm should be positioned against the RV cover.

Authors |

|

Mark Inman |

In our line of work, we field questions from contractors and technicians concerning repairs, installations and general backflow prevention practices. We’d like to share some questions that we receive, as well as our answers. Everyone has different opinions on these subjects and we would like to hear yours.

Contact us with questions and ideas via email at: or mail us at: |

Doug Taylor |

|

22 Dec 2020

22 Dec 2020

Posted by BP Journal

Posted by BP Journal