Perhaps the most important human need in our society is a supply of clean safe drinking water. It is also something that is commonly taken for granted by both the general public and by a large number of both tradesmen and utility officials. The number of backflow prevention devices installed improperly by both the professional contractor and the property owner or their maintenance personnel is reaching a level that is difficult to believe. Backflow prevention assemblies and devices must be installed in the proper manner so that they both can fulfill their purpose in protecting the water supply and also be tested and repaired in a safe, timely manner. They must also be protected from the elements in both warm and cold climates. Installation requirements are just that, requirements that must be met to insure both that the assembly or device will perform properly and also ensure the safety of the personnel that must both test and maintain the required backflow protection.

There are so many factors that must be considered with each and every installation:

- Degree of hazard

- Location

- Incoming pressure

- Pressure loss

- Thermal expansion

- System requirements

- Future requirements of the system

- Future hazards

The list goes on and on. In this article we will try to cover basic installation requirements while keeping in mind that each installation is different and presents new challenges. Depending on the requirements in your jurisdiction you may have a water supplier that requires containment or point of service protection on commercial and in some cases residential water services. The adopted plumbing code will also mandate isolation or point of use protection be installed at fixtures and appliances throughout each facility or residence. Being a person who has been working in the industry for the last forty two years installing and testing backflow prevention assemblies or training individuals for cross-connection certifications I am aware of the pressure that is exerted on many contractors and water suppliers by both the end users and the property owners to both keep the installation cost as low as possible and also to keep space requirements to a minimum. These factors can be a problem in new construction and are a nightmare in retrofit installations. Anyone who has tried to convince a factory owner that he must spend thousands dollars to install a backflow prevention assembly for containment protection that was not required to be installed when his building was first built to protect the other consumers on a water system knows what I am talking about and if you throw in fire sprinkler systems you are really in for a fight.

Although there are many ways an installation can go wrong the most common one, I have seen is the location of the assembly or device itself. From backflow assemblies installed in pits to other assemblies installed thirty feet in the air over industrial machines these valves can be an installer or backflow tester’s nightmare. Let us go over some basic installation requirements for the Reduced Pressure Principle Assembly (RPZ), the Reduced Pressure Principle Detector Assembly (RPDA), Double Check Valve Assembly (DCVA), the Double Check Detector Assembly (DCDA), the Pressure Vacuum Breaker Assembly (PVB), the Spill Resistant Vacuum Breaker Assembly (SVB) and the Atmospheric Vacuum Breaker (AVB).

When installing the AVB (figure one) several factors must be considered, the location of the device both in relation to spill protection and the elevation of the piping and equipment being served by the device. The AVB must be installed a minimum of six inches (check local codes) above all downstream piping and fixture flood rims. AVB’s installed as part of a piece of equipment can at times be “deck mounted” which allows the protection to be mounted one inch above its use. It must also be installed in an upright position and must never be subjected to continuous pressure for more than twelve hours. In the current model plumbing codes shutoff valves are prohibited downstream of the device, however at the last update of the ASSE 1001 AVB Product Standard in 2017 the language was changed from prohibiting valves downstream to now saying that “The device shall have its outlet open to atmosphere.” Changes have been proposed to the model plumbing codes which may allow for valves downstream of the AVB provided there is an open outlet to atmosphere between the AVB and any downstream valve. Depending on the application the AVB can be installed in both high and low hazard backsiphonage applications. The AVB only protects against back siphonage. It provides no protection against and is not designed any backpressure. This device is probably the most commonly misapplied backflow prevention product being installed in the field today. Plumbers find them installed below the fixture flood rim on everything from commercial garbage disposals to soap dispensers. When installed improperly they become just another expensive elbow in the system piping. Although this is a very simple device, the protection it provides to the potable water system when properly installed is critical to the public health.

When installing the AVB (figure one) several factors must be considered, the location of the device both in relation to spill protection and the elevation of the piping and equipment being served by the device. The AVB must be installed a minimum of six inches (check local codes) above all downstream piping and fixture flood rims. AVB’s installed as part of a piece of equipment can at times be “deck mounted” which allows the protection to be mounted one inch above its use. It must also be installed in an upright position and must never be subjected to continuous pressure for more than twelve hours. In the current model plumbing codes shutoff valves are prohibited downstream of the device, however at the last update of the ASSE 1001 AVB Product Standard in 2017 the language was changed from prohibiting valves downstream to now saying that “The device shall have its outlet open to atmosphere.” Changes have been proposed to the model plumbing codes which may allow for valves downstream of the AVB provided there is an open outlet to atmosphere between the AVB and any downstream valve. Depending on the application the AVB can be installed in both high and low hazard backsiphonage applications. The AVB only protects against back siphonage. It provides no protection against and is not designed any backpressure. This device is probably the most commonly misapplied backflow prevention product being installed in the field today. Plumbers find them installed below the fixture flood rim on everything from commercial garbage disposals to soap dispensers. When installed improperly they become just another expensive elbow in the system piping. Although this is a very simple device, the protection it provides to the potable water system when properly installed is critical to the public health.

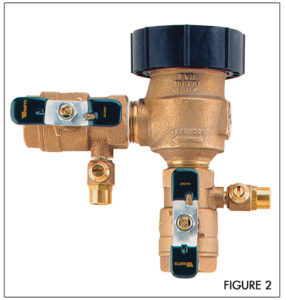

The PVB (figure two) is also used to prevent backsiphonage within the water system. This assembly while similar to the AVB can be used in many applications that require continuous pressure downstream of the device including hose reels. Downstream shutoffs are allowed, and the assembly is in-line testable and in-line repairable. As with any testable backflow prevention assembly the PVB has shutoff valves at the inlet and outlet of the valve body. These shutoff valves must be full port, resilient seated, and tightly closing (drip-tight). The PVB also contains two test cock strategically located for assembly testing the assembly’s components. The PVB requires a minimum of twelve inches elevation measured from the critical level of the assembly to grade and also to all downstream piping or equipment. It provides no protection against backpressure but is rated for both high and low hazard backsiphonage protection. The PVB must also be installed in an upright position and care must be taken as to the location of the assembly due to the possible water leakage from the air-inlet valve of the assembly as a result of a low pressure situation or valve component failure. PVB are used as isolation protection in many agricultural and lawn irrigation systems in addition to several types of industrial applications. As with any mechanical assembly care should be taken to ensure that they are installed in such a manner that they can be tested and repaired in-line. In colder climates freeze protection must also be considered.

The PVB (figure two) is also used to prevent backsiphonage within the water system. This assembly while similar to the AVB can be used in many applications that require continuous pressure downstream of the device including hose reels. Downstream shutoffs are allowed, and the assembly is in-line testable and in-line repairable. As with any testable backflow prevention assembly the PVB has shutoff valves at the inlet and outlet of the valve body. These shutoff valves must be full port, resilient seated, and tightly closing (drip-tight). The PVB also contains two test cock strategically located for assembly testing the assembly’s components. The PVB requires a minimum of twelve inches elevation measured from the critical level of the assembly to grade and also to all downstream piping or equipment. It provides no protection against backpressure but is rated for both high and low hazard backsiphonage protection. The PVB must also be installed in an upright position and care must be taken as to the location of the assembly due to the possible water leakage from the air-inlet valve of the assembly as a result of a low pressure situation or valve component failure. PVB are used as isolation protection in many agricultural and lawn irrigation systems in addition to several types of industrial applications. As with any mechanical assembly care should be taken to ensure that they are installed in such a manner that they can be tested and repaired in-line. In colder climates freeze protection must also be considered.

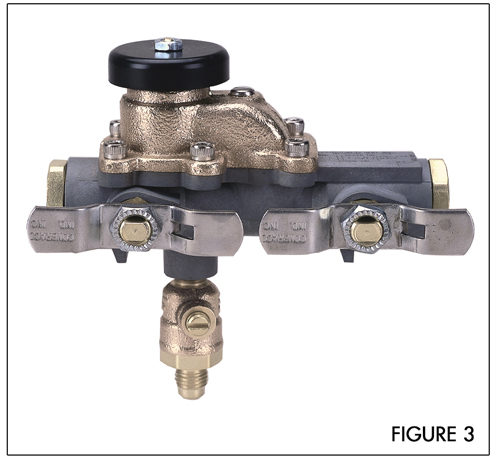

The cross-connection industry is one that adapts and changes to meet any specific installation or protection issue. Vacuum breakers are a perfect example of this. The AVB had its limitations and could not be used in systems that required continuous pressure so the PVB was developed. The PVB was good for continuous pressure but in low pressure situations could spill a large amount of water when the air-inlet failed to close and could cause damage as a result. The industry then stepped forward and developed the SVB (figure three) for high and low hazard backsiphonage protection and indoor use. Similar in construction to the PVB but with a design to cure the spillage problems that plagued the PVB. The SVB is required to be installed a minimum of twelve inches above grade and all downstream piping and fixtures. This testable assembly is also in-line repairable and is considerably more expensive than either a PVB or AVB. As with the other vacuum breaker types the SVB does not protect against and should not be subjected to any backpressure.

The cross-connection industry is one that adapts and changes to meet any specific installation or protection issue. Vacuum breakers are a perfect example of this. The AVB had its limitations and could not be used in systems that required continuous pressure so the PVB was developed. The PVB was good for continuous pressure but in low pressure situations could spill a large amount of water when the air-inlet failed to close and could cause damage as a result. The industry then stepped forward and developed the SVB (figure three) for high and low hazard backsiphonage protection and indoor use. Similar in construction to the PVB but with a design to cure the spillage problems that plagued the PVB. The SVB is required to be installed a minimum of twelve inches above grade and all downstream piping and fixtures. This testable assembly is also in-line repairable and is considerably more expensive than either a PVB or AVB. As with the other vacuum breaker types the SVB does not protect against and should not be subjected to any backpressure.

When the system requires protection against both types of backflow (backsiphonage and backpressure) the system designer or installer must consider several different factors when specifying the proper assembly needed. The degree of hazard must be the most important consideration outweighing all others in this decision. Once the decision on the type of protection needed has been made many other factors come into play, including space requirements, pressure loss and freeze protection just to name a few. Whether installing assemblies for isolation (point of use) or containment (service connection) protection the same installation guidelines should always be followed.

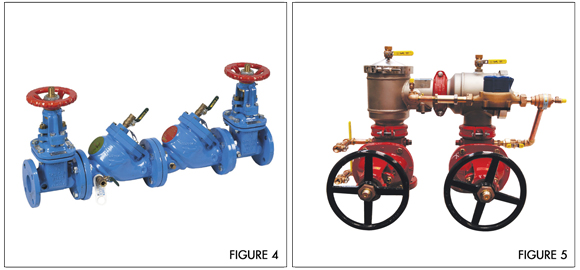

The DCVA (figure four) and DCDA (figure five) are designed to protect against both backsiphonage and backpressure in low hazard applications. The DCVA is used in a wide range of plumbing installations on both fixtures and equipment. It is also commonly found at the service connection providing containment protection at many low hazard buildings. The DCDA are installed on fire systems that do not contain any type of chemical additives or antifreezes. The DCDA contains a bypass which includes a water meter or flow indicator which will detect low flow pointing to a system leak or unauthorized water usage. Many of these assemblies are installed in meter pits or vaults as containment devices. As someone who has done a fair amount of assembly testing in the field, I can say that very seldom do you find a vault that has any sort of adequate drainage provided. Most pits have water in them, and it is a common occurrence finding the backflow assembly completely submerged in several feet of stagnant water. When you factor in the added expense for future testing and valve maintenance due to confined space requirements along with the almost impossible task of providing adequate drainage it is easy to conclude that pit or vault installations should be discouraged whenever possible. DCVA should be installed a minimum of twelve inches and a maximum of sixty inches above the ground or floor. These assemblies must be installed with adequate side and top clearances for both testing and maintenance. At least twelve inches should be provided around the valve, with twenty-four inches at the test cocks. When you are installing larger assemblies, greater clearances may be required.

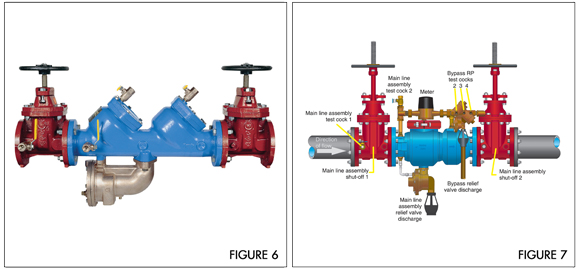

The RPZ (figure six) and the RPDA (figure seven) are the best backflow protection the designer or installer can provide short of the physical air gap. The RPZ and RPDA protect against both backpressure and backsiphonage and can be used in low and high hazard installation. They are installed for both point of use and containment protection. Because these assemblies incorporate a relief port that may be open to the atmosphere, they should never be installed without proper drainage being assured or in a pit or vault.

RPZ’s and DCVA’s assemblies can present great difficulties when installed in pits or vaults. A large assembly may require a drain line so large that it makes a pit or vault installation impossible. At least twelve inches should be provided around the valve, with twenty-four inches at the test cocks. When you are installing larger assemblies, greater clearances may be required. This assembly should be installed at least twelve inches above the ground or floor and not more than sixty inches to the bottom of the assembly. When installing an RPZ a drain must be provided for the relief port. These assemblies are being installed in closets, ceilings, and many other locations with no provisions being made for water spillage due to valve failure, line pressure fluctuation or any of the many reasons for relief port discharge. The damage from these improperly installed valves can be staggering.

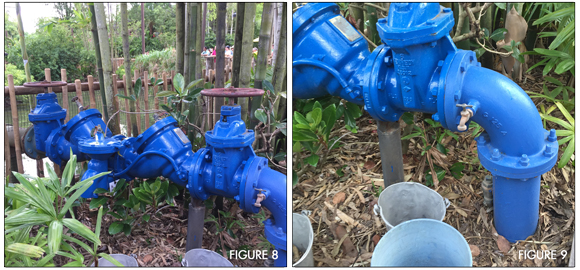

The photos in figures eight and nine show how things go wrong with valve selection. In figure eight, the RPZ is installed as isolation protection on the make-up water supply to an artificial lagoon. This six-inch assembly was installed at a cost of several thousand dollars. The problem here is that the assembly is unnecessary. There is a ten-foot airgap between the end of the water supply and the overflow height of the lagoon. In figure nine, we can see that upstream of the RPZ there is an unprotected hose bibb. Thousands of dollars of protection that is not needed installed and an inexpensive hose bibb vacuum breaker missing resulting in an unprotected cross connection. Things like this occur far too often.

The solution to many of these problems is simple. Choose the proper assembly or device that is needed for the protection required. Ensure it is installed in the proper position, follow the manufacturers installation instructions, check your local codes, and for backflow prevention assemblies have them tested at a minimum annually by a certified tester. As the ASSE motto says “Prevention Rather that Cure” by following these few simple guidelines the public water system can be protected.

About the Author |

|

|

Sean is a 40 year member of the United Association Local 524 Scranton Pa. He has worked in all phases of the plumbing and mechanical industry and is a licensed master plumber. Sean is a Past President of the American Society of Sanitary Engineering. Sean is also the member of the ASSE Cross-Connection Control, Technical Committee. Sean is employed by IAPMO as the Vice President of Operations for the IAPMO Backflow Prevention Institute. |

26 Aug 2020

26 Aug 2020

Posted by Sean Cleary

Posted by Sean Cleary