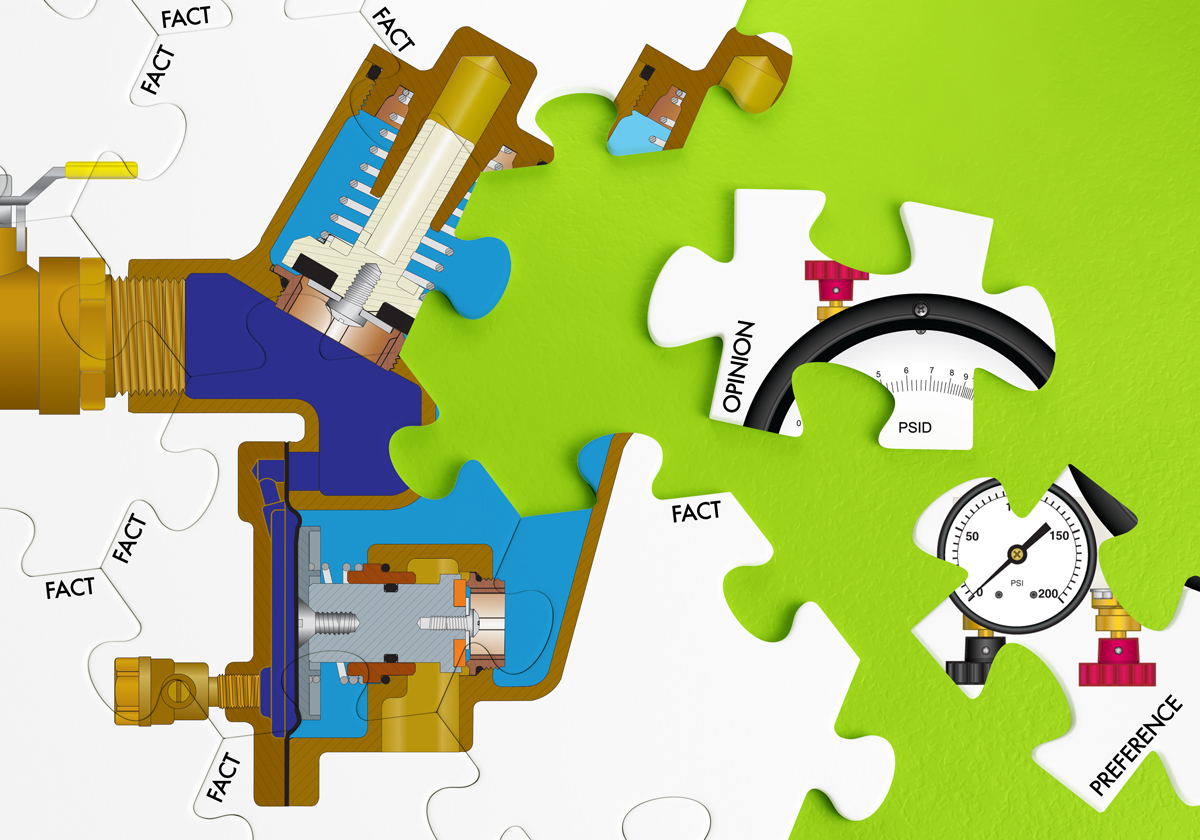

Let us start this conversation with a few definitions of some words so we are all on the same page. The words are fact, opinion, and preference. The word fact is defined as: a thing that is known or proved to be true or the truth about events as opposed to interpretation. The word opinion is defined as: a view or judgment formed about something, not necessarily based on fact or knowledge. The word preference is defined as: a greater liking for one alternative over another or others. The meaning of these words is very different but some individuals in our industry seem to be confused about the true meaning of each word. Another important word is the word perception. That is defined as: a way of regarding, understanding, or interpreting something. We need to think of these words and what they mean when we look at policy decisions and how rules and regulations are created.

When we look at problems and solutions in the cross-connection industry the guiding principle in any discussion should be based on the Facts that exist. That is how we ensure the protection of our water systems. In far too many areas it is opinions or personal preferences that seem to be driving the bus. Situations are occurring where because of an opinion or a personal preference, policies or regulations are being changed to come up with a solution to a problem that does not exist. There is no factual basis for the change but programs that have been in place for many years suddenly must be changed. Once the changed is announced we then build a narrative to make a change seem necessary. It is like the police deciding who committed the crime before any crime has taken place and then putting a case together to prove what they have already decided on in advance, not doing any real investigations and discounting any facts that did not reinforce their original decision.

Those of us in the cross-connection industry should have one goal in mind at all times. That is to make sure programs are in place to ensure that the public water system is protected at all times, that people can use the water supplied to them without worry, and that their health and wellbeing is the most important consideration in everyone’s mind. To do that we need to know that the backflow preventers we install will protect against backflow when installed correctly. We do that by making sure backflow preventers are built to the correct product standards and go through a rigorous program of testing conducted by a party independent of the manufacturer to make sure the assemblies will function as designed when they are installed in the field. This is why we have listing programs for backflow prevention assemblies. We also need to ensure backflow protection is installed where needed and that the type of method, assembly, or device that is installed provides the correct level of hazard protection and will prevent any type of backflow which may occur. We then need to test and maintain the protection that is installed. In order to do that several groups need to work together to make that happen.

This is where we need to think about the enormous difference between the word’s fact, opinion, and preference and work to make sure that the facts of the case are the deciding factor in these policies and decisions. This is where the system breaks down in many areas. Sometimes the issues are small problems. In other situations, these issues can cause large problems that work against our industry goal of providing clean safe drinking water.

If we look at any area of the country several groups need to work together to ensure a robust cross-connection program is in place. The water supplier has a large role in containment protection. The plumbing industry plays a vital role in the proper installation of any required protection for either containment or isolation protection. The inspection community must understand backflow prevention and cross-connection control to allow them to ensure that the proper protection is installed and installed correctly. The same goes for the designers of buildings and the water system they include. Certified testers need to be there to provide the assembly testing necessary in any strong and sustainable program. When everyone works together a better program is the result and the protection of the public water system is a much easier goal to achieve. Groups need to work together and to respect each other’s role in this process. We need to spend our time and treasure on the things that really matter.

In too many locations that is not the case. Instead the groups spend their time and energy on things that do not advance the cause. We fight over specific test procedures instead of fighting to make sure that all assemblies including isolation protection assemblies are tested annually. We look to limit what quality third party certifications are accepted in the jurisdiction instead of working together to ensure that only certifications from third party certifiers are accepted and that single party certifications become a thing of the past. If the same person or group does the training, writes the exam, corrects the exam, proctors the exams, collects the money, and hands out the certification how can we possible ensure the testing or training is done correctly.

I know of one of these schools in the northern part of our country that conducts two-day, three-day, and four-day tester certification classes in the same location, with the same person acting as both the instructor and proctor. The classes all run together during the same week with individuals in the 32-hour class in attendance for all four days, the 24-hour class there for second through fourth day, and the 16 hour class there for only days three and four. The length of time the student attends the class is based on what the jurisdiction they are from requires. Class size seems to be based on however many people pay to attend. The wet lab consists of one of each assembly type and one test kit. The class I observed had 23 people in it on test day. Everyone passed the exam and became certified. Working against this type of certification and raising the bar in the industry is so much more important that fighting over what specific test procedure your certified testers are using.

Several years ago, a number of industry groups a developed position paper on minimum requirements for tester training and certification. It was a step forward with people working together in an attempt to find consensus. These meetings were productive and a needed step to move the industry forward. The position paper can be found at: http://www.iapmodwbp.org/bpi/industry-position-papers/tester-education-training-n-certification

This same group also put together a statement on when and how often backflow prevention assemblies should be tested. The group realized that the assemblies being tested was the most important statement we could make. We stayed out of the procedure specific argument understanding that the assemblies being tested was the critical point we were trying to make. Members of the group do have their opinions and preferences on which specific field test procedures they think should be used or they feel are more accurate, but the industry is far from being in agreement on that issue. The fact is that a number of field test procedures can be used to accurately evaluate backflow prevention assemblies. Sadly, these meetings are no longer taking place although I am hopeful that we can restart them in the future. Work schedules and other factors including personalities and industry politics on all sides have slowed down progress, but the work is to important and there are too many dedicated people out there for this project not to be restarted. There is more work to be done.

These words fact, opinion, and preference are not the same and are not interchangeable. Facts are what are important in any debate or discussion. Closed minds, politics, and personal preference do not solve problems or move our industry forward. In fighting for a better cross-connection control program the least important factor for you to spend all your time and treasure working to achieve is the acceptance of a single certifier and single test procedure in order to create a monopoly is short sighted and counterproductive. There are better ways to spend your time.

About the Author |

|

|

Sean is a 40 year member of the United Association Local 524 Scranton Pa. He has worked in all phases of the plumbing and mechanical industry and is a licensed master plumber. Sean is a Past President of the American Society of Sanitary Engineering. Sean is also the member of the ASSE Cross-Connection Control, Technical Committee. Sean is employed by IAPMO as the Vice President of Operations for the IAPMO Backflow Prevention Institute. |

26 Aug 2020

26 Aug 2020

Posted by Sean Cleary

Posted by Sean Cleary

1 Comment

Sean,

Your ability to write exceeds my ability to reply, but let me say that clarity is a virtue and facts make things clear. While I enjoy my perception of your message, I even more respect the facts you point out.

May I share the link as it is in its complete form with others as an example of what our industry does and stands for?

“Protecting the health and safety of the nation…”

Greg Chick, contractor since 1976′