The word containment in the cross-connection industry is an important one. The IAPMO Backflow Prevention Manual lists the definition as: The water suppliers backflow prevention policy of installing protection after the public distribution system service connection and prior to any branch in the water distribution system. It is also called “point of service” protection. The installation of backflow protection at the service connection provides protection to the public distribution isolating that system from the customers water system. It provides no protection to the consumers within a facility. In fact, in the event of a backflow incident within the consumers system, it will prevent the dilution of any substance in the water back into the public system. That is why containment is not the end of a successful cross-connection program, it is only one component of it. The other necessary step is an aggressive isolation protection program.

Many disagree with the need for both isolation and containment protection programs, and in truth, if a system has the correct isolation protection at each fixture or appliance, we could eliminate the need for containment protection. However, in the real world because of possible modifications and changes to any existing systems it is imperative that the second line of defense for the public system must be in place. The containment assemblies and devices provide that protection.

Cross-connection surveys are the way we determine what type of backflow protection is required. An isolation survey is a comprehensive look at the entire water system within a facility. In an isolation survey you need to look at all potable water piping, outlets, and fixtures, as well as the drainage connections of these fixtures. The surveyor must also record all areas requiring backflow protection. It is also necessary to determine the degree of hazard of any cross-connections that are found. It also looks at any existing backflow prevention, methods, devices, and assemblies. It concludes with a detailed report and a follow up inspection after all the corrections are completed.

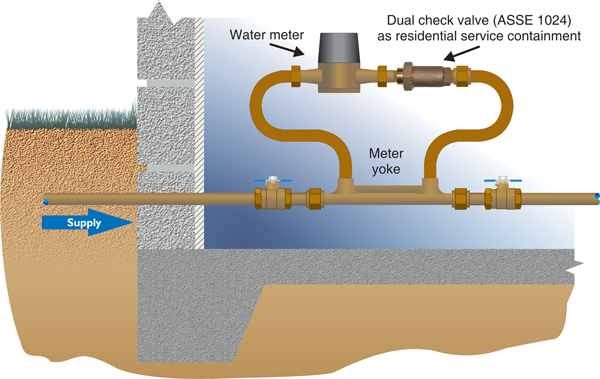

A containment survey is a simpler and more straightforward endeavor. In it we would identify the degree of hazard inherent within the facility. We would then inspect the potable water entrance to the facility, the water service connection, and the meter location for the correct protection method, device, or assembly based on the type of hazard present within the facility. We would prepare a detailed report on the necessary changes, if needed, and schedule a follow up inspection after any required corrections are completed.

Once we know the degree of hazard for the facility or residence, we can decide on the type of protection needed and the proper location and installation of cross-connection control protection. Water purveyors vary on their requirements for containment protection. In my area PA American Water requires a dual check valve be installed for residential containment protection.

They tell their customers the following: A dual check valve is a device used to ensure that water flows in a single direction. Proper installation of a dual check valve is required by Pennsylvania American Water’s filed water tariff as it prevents water from flowing out of a customer’s residence and back into the public water supply system, protecting against potential contamination. To their credit they do warn their customers about possible thermal expansion problems that may result after the dual check is installed on the residential water service line. PA American Water does not look at hazard conditions related to residential water services or residential customers. On commercial services PA American Water mandates that customers fill out a Customers Cross-Connection Control and Backflow Protection Survey Form and e-mail or fax it back to the company. They tell customers to: Complete our survey and fax it back to us. We will help determine whether you are in compliance with cross-connection/backflow prevention regulations

PA American will then look at the survey and decide the level of protection needed at the customers service connection. The survey asks user how they are using water at the facility. It asks customers if they are using water in bathrooms, drinking fountains, outside water faucets, household laundry or dishwashing appliances. Do private wells supply any part of your facility? Is any water piped into a manufacturing process or piped into any type of chemical process? Is water piped, into any type of underground lawn sprinkler/irrigation system? Do they supply a swimming pool? Is water used in any water operated equipment, appliances or boilers? Is water supplying medical, pathology, research chemical, bacteriological labs or photo processing lab.

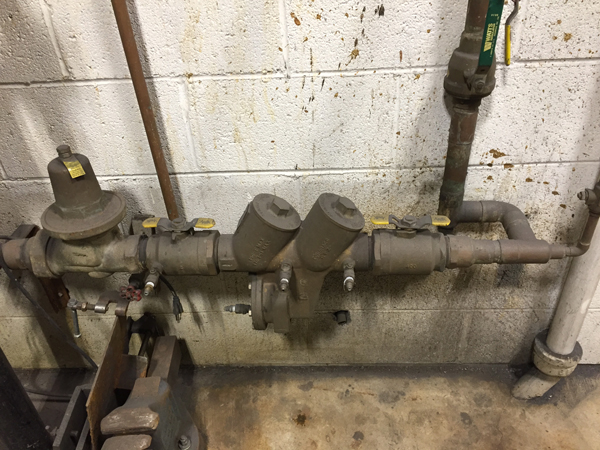

Other purveyors may require in person surveys of a facility. Some facilities are simply a high hazard situation based on the type of work done there. A waste water treatment plant, as an example, will always require the installation of a reduced pressure principle backflow prevention assembly as the required containment protection. Other high hazard facilities include hospitals, mortuaries, plating plants, power plants, tanneries, and any facilities that have auxiliary water systems or auxiliary wells. The secret is looking at a facility or residence and their water usage and then deciding what is needed based on the degree of hazard and the type of backflow the system may experience.

Installing containment protection on existing systems is also an issue. The installation of any type of cross-connection protection will change the hydraulic conditions within that system. Both pressure and volume will be lost. A closed water system will also be created. Thermal expansion becomes an issue and the residual minimum pressure within the system can be a factor. In some situations, simply finding the room needed within a buildings meter or mechanical room can be a challenge. Drainage requirements for larger assemblies can also be a factor that must be considered.

When we look at new construction projects it is important to realize that containment protection is not something that is addressed in a permitting or plan review process. Containment protection is not addressed in any of the model plumbing codes. The plumbing code addresses isolation protection only. That is why it is always a critical step to contact the water purveyor and see what their specific regulations and requirements are for containment protection. Common sense should also be used in deciding on what protection is needed. A good rule of thumb (a broadly accurate guide or principle, based on experience or practice rather than theory) is that the protection installed as containment protection should match the highest hazard within a building or residence. As an example, a building containing a hydronic heating system treated with chemicals or antifreeze would, according to the plumbing code, be protected by the installation of a reduced pressure principle assembly. In this type of situation, the containment protection should match the highest protection with the facility and a reduced pressure principle assembly should be installed at the service connection.

Therefore, it is important to look at each location as a stand-alone system. Water purveyors looking at residential properties and just making a blanket decision that low hazard non-testable protection is required are putting the public water system at risk. Irrigation systems, water reuse, snowmelt systems, and a number of other usages that are becoming more and more common should at a minimum require a residential survey form, if not an in person survey. Many jurisdictions do not track or police the testing or repair of isolation backflow prevention assemblies on residential properties. Some do not look at isolation protection even on industrial or commercial properties. This is why the proper containment protection is necessary on all water services no matter the building type. In many cases a non-testable dual check may indeed be the proper protection but to simply assume that it is correct is not the correct way to protect your water system.

Backflow protection is a proactive program. We look at what is the worst possible scenario and then install the proper protection to ensure a backflow incident cannot happen. We then mandate the testing and maintenance of that protection to keep it in working order. We don’t report when bad things happen or clean up after an issue occurs. Our programs need to prevent the problem from ever taking place. To do that we need an aggressive, well-run program, with specific defendable policies in place. Cross-connection control is not a one-size fits all solution.

The American Society of Sanitary Engineering has a motto. “Prevention Rather Than Cure” It is what we strive for in the cross-connection industry. Lets take care of any potential problem before it occurs by having the correct protection in place.

About the Author |

|

|

Sean is a 40 year member of the United Association Local 524 Scranton Pa. He has worked in all phases of the plumbing and mechanical industry and is a licensed master plumber. Sean is a Past President of the American Society of Sanitary Engineering. Sean is also the member of the ASSE Cross-Connection Control, Technical Committee. Sean is employed by IAPMO as the Vice President of Operations for the IAPMO Backflow Prevention Institute. |

01 May 2019

01 May 2019

Posted by Sean Cleary

Posted by Sean Cleary

3 Comments

As usual, great article Sean! Can I share this with our hundreds of water purveyors nation-wide? Tom – Aqua Backflow / TrackMyBackflow.com.

It can be difficult to convince plumbing professionals of the need for commensurate containment protection. Great article for Administrators of programs to help convey this message to plumbing professionals, persons in leadership, and our customers. Thank you Sean!

Awesome Article