I need to service a 4” Wilkins 950DA backflow assembly. The check valves on the mainline assembly are failing and I want to change out the check rubbers and replace the seats. Can you tell me about this assembly and what to expect during this repair?

Mark:

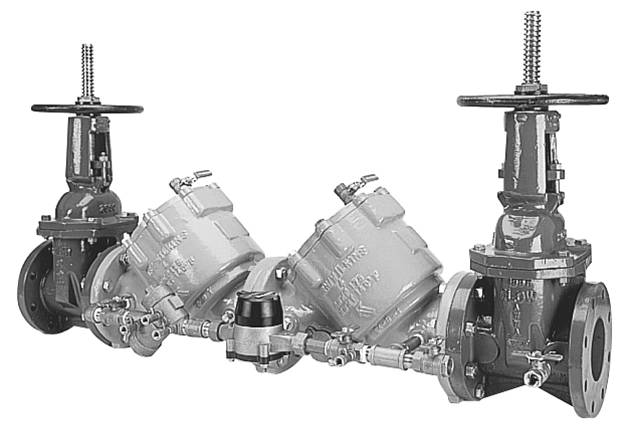

The Wilkins 950DA is a double check detector assembly that was manufactured in 2 1/2” through 10” sizes. Production of this model began in 1991 and was discontinued in 2004. The body is made of ductile iron and has a blue epoxy coating. The bypass assembly used for this model is a 3/4” 950XL double check valve assembly. No special tools are required to change the check discs or check seats for this model.

Doug:

The access covers will have to be removed in order to service the check valves. The covers are o-ring sealed and secured by bolts. There is a slight spring load on the cover, but the check springs are completely contained. Loosen the bolts slowly about 1/2” until the spring tension is released. Once you verify that the pressure is off the cover, then go ahead and remove the bolts and cover.

Mark:

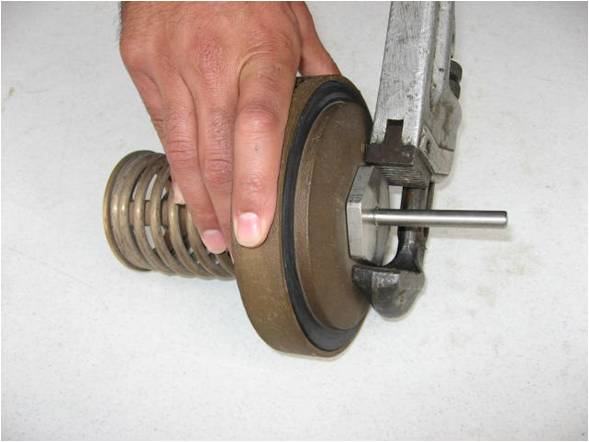

This assembly utilizes center stem guided check valve assemblies. Once the cover has been removed, the checks can be lifted up and out of the seat and body. Be careful to not hit or nick the inside epoxy coating when removing the checks. The spring tension does not have to be released to replace the rubber disc. Unthread the retaining nut from the stem and remove the stainless disc retainer. The rubber disc is now free to be replaced.

Doug:

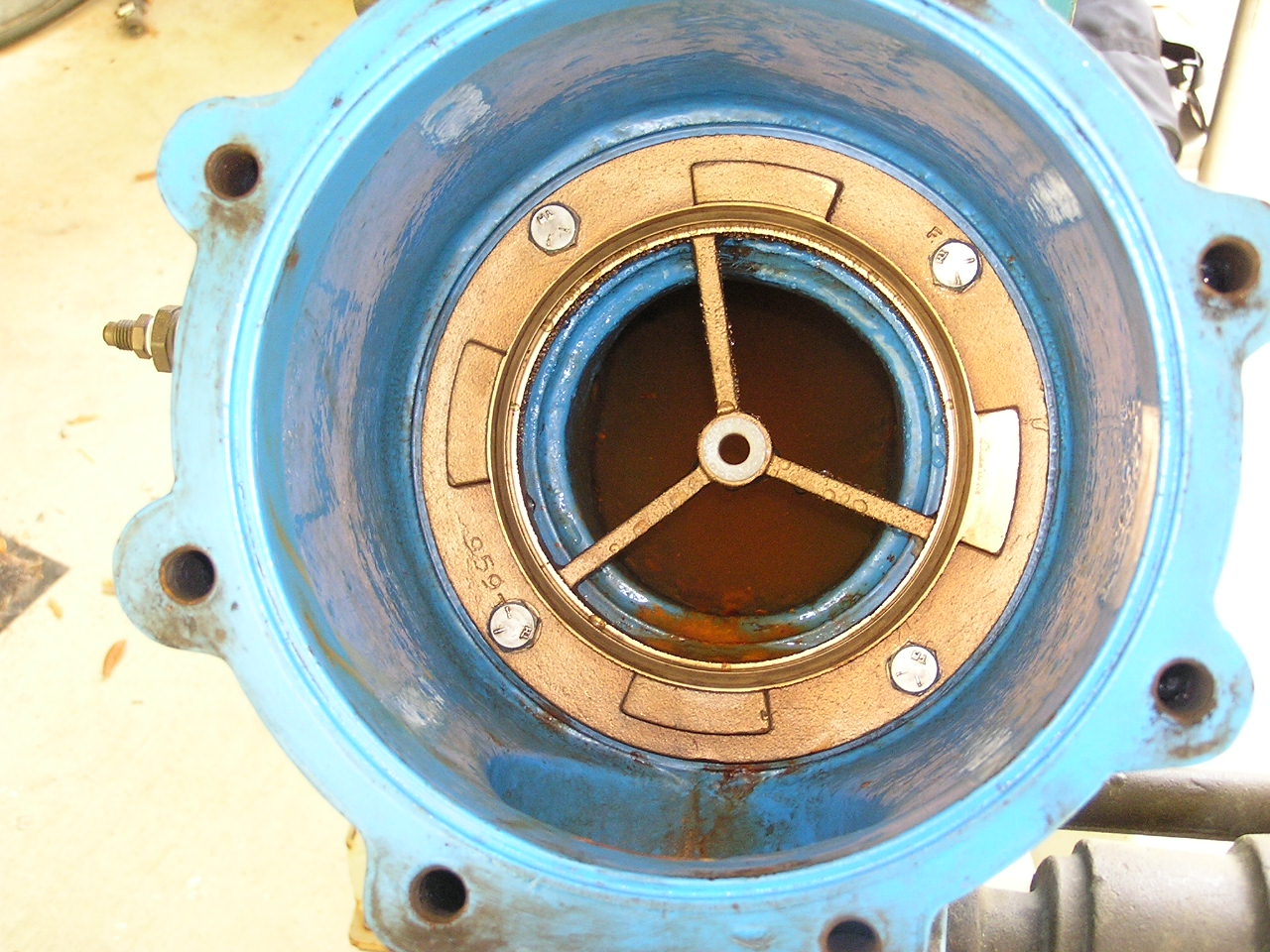

The check seats for the 950DA are bolted into the body and sealed by an o-ring. Simply remove the four retaining bolts and pull the seat straight out of the body. When installing the new seat, be sure to inspect the epoxy coating on the surface where the o-ring will seal. If the epoxy has been worn away to bare metal, the new seat and o-ring may not seal properly. In that case the assembly may need to be replaced.

Authors |

|

Mark Inman |

In our line of work, we field questions from contractors and technicians concerning repairs, installations and general backflow prevention practices. We’d like to share some questions that we receive, as well as our answers. Everyone has different opinions on these subjects and we would like to hear yours.

Contact us with questions and ideas via email at: or mail us at: |

Doug Taylor |

|

23 Apr 2019

23 Apr 2019

Posted by BP Journal

Posted by BP Journal

1 Comment

I repaired on using the rubber kit last week. Very easy backflow to work with. I was initially unsure of how much spring tension was on the lid but once I removed it noticed it would just push a little bit.